Electronics Manufacturing Services (EMS)

Precision EMS for High-reliability Applications

SMT | THT | Box Build | Mechatronics Assembly - All under one roof

Compliance & Certifications

At Unitech, our EMS division is built to handle everything from rapid prototyping to medium and high-volume

production with a strong focus on flexibility and quality. We support high-mix, low-to-mid volume

manufacturing without strict MoQ restrictions, making us an ideal partner for both pilot builds and scaled

production. We are currently serving primarily to the automotive and medical industries and are rapidly expanding

to other industries like industrial electronics & Defense.

Our facility spans 15,000 sq. ft., equipped with two high-speed SMT lines delivering a combined capacity of 1.5

lakh CPH. We are capable of placing a wide range of components including 0201, 01005, QFP, QFN, BGA, and

Micro BGA packages.

We follow IPC Class 2 & Class 3 standards for PCB assembly and box builds, ensuring reliability for critical

applications. Quality assurance is built into every stage, supported by in-line AOI and X-ray inspection systems.

A SAP/MES-driven traceability system provides complete process visibility.

Electronics Manufacturing Services (EMS)

Prototyping

Rapid prototyping and small-batch production to validate designs quickly and accelerate time-to-market.

PCB Assembly (SMT & THT)

State-of-the-art Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly, supporting multi-layer PCBAs for various applications.

Component Sourcing & Supply Chain

Dedicated sourcing expert ensure reliable, traceable procurement of componenets, with Vendor qualification and risk-managed alternate sourcing.

Box Build & Electromechanical Assembly

We offer end-to-end assembly solutions, including PCBAs, enclosures, wire harnessing, mechanical, integration, and final testing, ensuring a turnkey solution for OEMs.

Testing & Quality Assurance

In-circuit Testing ensures performance & reliability using custom testers. Comprehensive Quality inspections and AOI ensure zero-defect products meeting international standards.

Capabilities

SMT (Surface Mount Technology) Lines

2 High Speed SMT Lines

- With a 10K class clean room facility.

- With a capacity of up to 2,00,000 cph

Our SMT Lines consist of the following equipments

Fully Automatic Screen Printers

Delivers precise solder paste deposition for consistent,

high-yield assemblies

Inline 3D Solder Paste Inspective (SPI)

Checks solder paste height and volume inline, preventing

defects before placement

High-Precision Pick & Place Machines

Our Yamaha YRM20 high-speed placement system ensures

micron-level accuracy for components from 01005 chips to

complex BGAs, guaranteeing both speed and flexibility in assembly

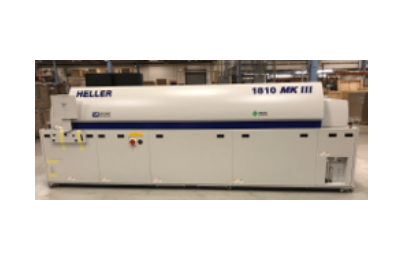

Reflow Ovens with Precise Thermal Profiling

We use Heller 10+3 zone reflow ovens with nitrogen atmosphere, delivering perfect solder joints and void-free connections through advanced thermal profiling.

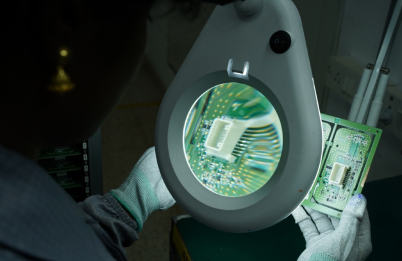

Inline 3D Automated Optical Inspection (AOI)

Inline Yamaha AOI systems check solder joints, polarity and placement in real time, ensuring zero-defect boards.

THT (Through Hole Technology) Lines

Our production line includes the following equipments

Selective Soldering Machines

Delivers consistent through-hole

soldering with precision and repeatability.

Wave Soldering Machines

Ideal for high-volume THT, ensuring

strong and uniform solder joints.

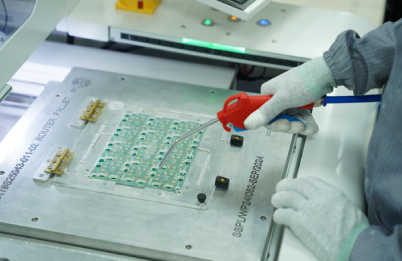

Routing Machine

Stress-free PCB depaneling prevents cracks

and protects delicate components.

In-circuit Testing

Ensures every board is defect-free and

performs under real-world conditions.

Conformal Coating & Potting

Automated coating protects PCBs from dust, moisture, and harsh environments.

Products

PCBA + Box Build

AUTOMOTIVE PRODUCTS

Climate Control Unit

Head Lamp & Tail Lamp

Overhead Console Lamp

Instrument Cluster Units

Steering Wheel - Multifunction button control switch

Steering Wheel – Combination Switch

MEDICAL PRODUCTS

Pulse Oximeter